Operator's Manual

Figure 49

1. Slotted Nut 3. Hole in threaded shaft

2. Two threads or less

showing

4. Washer (if needed)

5. Chec k the distance from bottom of slot in n ut

to inside edg e of hole . T w o threads or less

should be sho wing ( Figure 49 ).

6. If more than tw o threads are sho wing remo v e

n ut and install w asher betw een hub and n ut.

7. T or que the slotted n ut to 125 ft-lb (170 N ⋅ m)

( Figure 49 ).

8. Tighten the n ut until the next set of slots line

up with the hole in the shaft ( Figure 49 ).

9. R e place the cotter pin.

Adjusting the Caster Pivot

Bearing

Chec k after ev er y 500 operating hours or at

storag e , whic h ev er comes first.

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

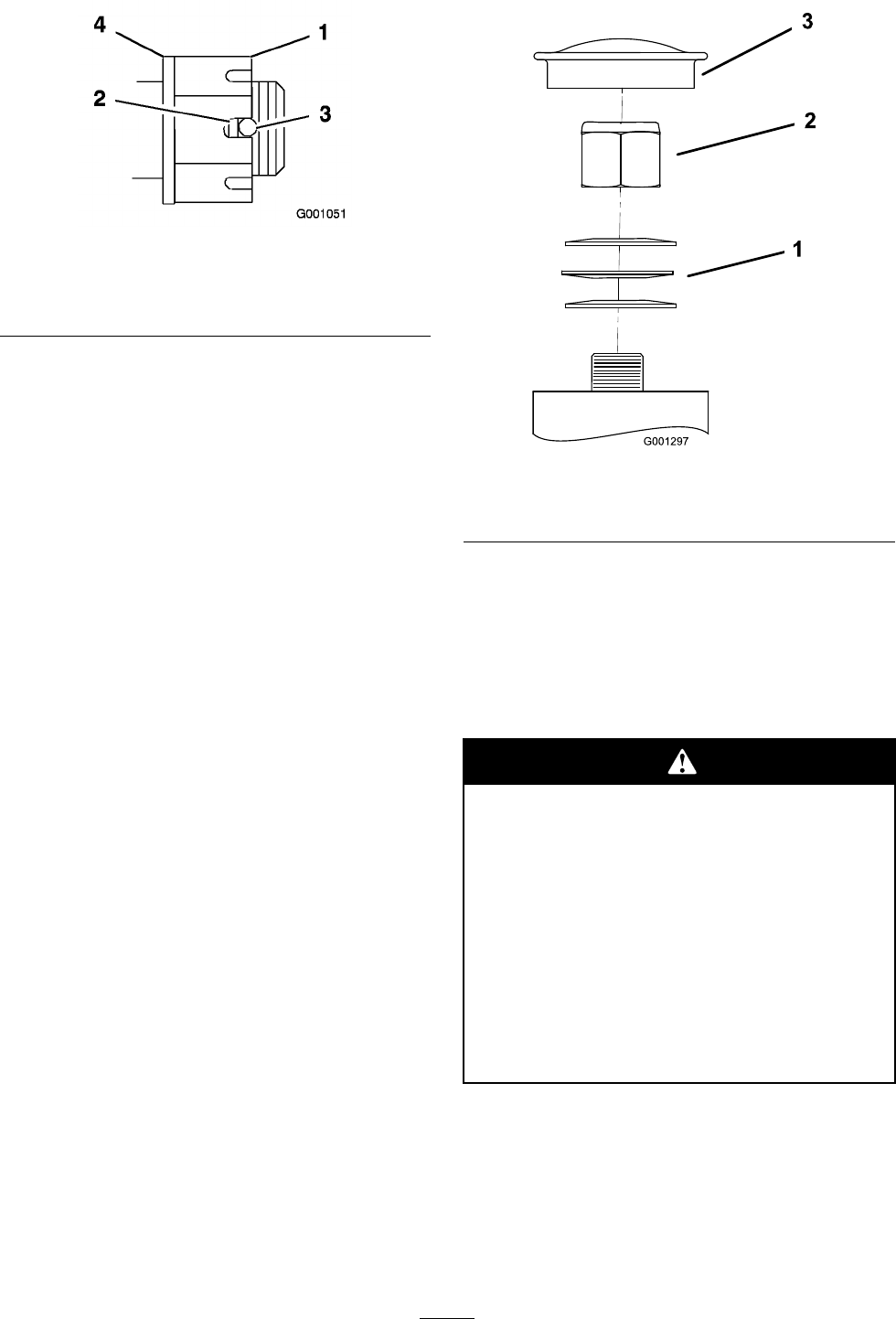

3. R emo v e the dust cap from caster and tighten

loc k n ut ( Figure 50 ).

4. Tighten the loc kn ut until the spring w ashers

are flat and then bac k off a 1/4 tur n to properly

set the pre-load on the bearings ( Figure 50 ).

Important: Mak e sur e spring w asher s

ar e installed cor r ectl y as sho wn in

Figur e 50 .

5. Install the dust cap ( Figure 50 ).

Figure 50

1. Spring Washers

3. Dust Cap

2. Lock Nut

Cooling System

Maintenance

Servicing the Cooling System

Discharge of hot pr essuriz ed coolant or

touching hot radiator and sur r ounding par ts

can cause sev er e bur ns.

• Do not r emo v e the radiator cap when

the engine is hot. Al w ays allo w the

engine to cool at least 15 min utes or

until the radiator cap is cool enough to

touch without bur ning y our hand bef or e

r emo ving the radiator cap .

• Do not touch radiator and sur r ounding

par ts that ar e hot.

41