Service Manual

Table Of Contents

- Revision History

- Preface

- Chapter 1 : Safety

- Chapter 2 : Specifications and Maintenance

- Chapter 3 : Troubleshooting

- Chapter 4 : Engine

- Chapter 5 : Chassis

- General Information

- Service and Repairs

- Right Console Replacement

- Left Console Replacement

- Throttle Cable Assembly Replacement

- Choke Cable Assembly Replacement

- Seat Replacement

- MYRIDE® Replacement

- Fuel Tank Replacement

- Park Brake Handle Assembly Replacement

- ROPS (Roll Over Protection System) Replacement

- Caster Fork and Bearing Replacement

- Caster Wheel Rebuild

- Motion Control Assembly Replacement

- Chapter 6 : Deck

- Chapter 7 : Drive System

- Chapter 8 : Electrical

- Appendix A: Foldout Drawings

- Electrical Schematic

- Electrical PTO Engaged Schematic

- Electrical Run Position

- Electrical Start Position

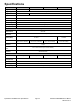

StandardTorqueforDry,ZincPlated,andSteelFasteners(MetricSeries)

Class8.8Bolts,Screws,StudswithRegular

HeightNuts(Class8orStrongerNuts)

Class10.9Bolts,Screws,StudswithRegular

HeightNuts(Class10orstrongerNuts)

ThreadSize

in-lbN•cmin-lbN•cm

M5X0.857±6644±6878±8881±90

M6X1.096±101085±113133±141503±158

ft-lb

N•m

ft-lb

N•m

M8X1.2519±226±328±338±4

M10X1.538±452±554±673±8

M12X1.7566±790±1093±10126±14

M16X2.0166±17255±23229±23310±31

M20X2.5325±33440±45450±46610±62

Note:Reducetorquevalueslistedinthetableaboveby25%forlubricatedfasteners.Lubricated

fastenersaredenedasthreadscoatedwithalubricantsuchasoil,graphite,orthreadsealantsuch

asLoctite.

Torquevaluesmayhavetobereducedwheninstallingfastenersintothreadedaluminumorbrass.The

specictorquevalueshouldbedeterminedbasedonthefastenersize,thealuminumorbasematerial

strength,lengthofthreadengagement,etc.

Thenominaltorquevalueslistedabovearebasedon75%oftheminimumproofloadspeciedinSAE

J1199.Thetoleranceisapproximately±10%ofthenominaltorquevalue.Thinheightnutsincludejam

nuts.

SpecicationsandMaintenance:TorqueSpecications

Page2–10

4000SeriesZMASTER®ServiceManual

3442-427RevA