Service Bulletin

Customer Service Bulletin Vehicles 08-20 Page 5 of 7

Hardened Sprayer Pump Heads Multi Pro 5800/1750/Workman January 17, 2017

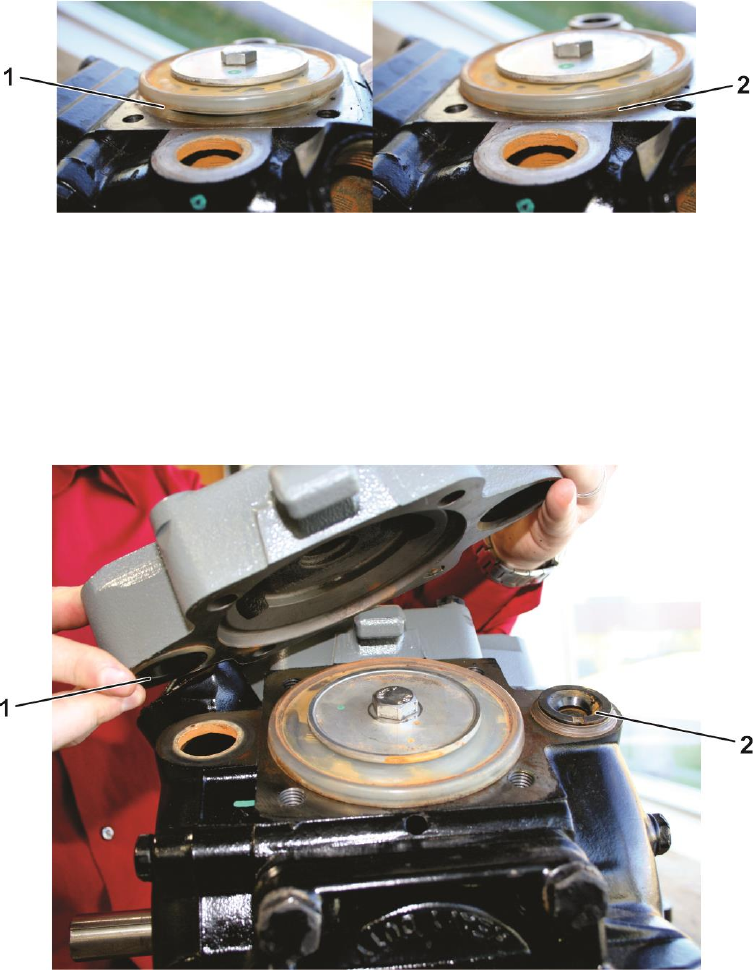

4. As you install each successive new pump head, turn the pump crankshaft to move each

diaphragm to its lowest position. There should be no gap between the diaphragm and the

surface of the pump case. See Figure 4.

Figure 4

1. Diaphragm gap, indicating incorrect crankshaft position

2. Diaphragm is flush with pump case surface, indicating correct

crankshaft position

5. When installing a pump head, ensure the inlet and outlet valves remain seated in their

proper position. Holding the inlet valve in its respective port while placing the pump head in

position is the best way to accomplish this. See Figure 5.

Figure 5

1. Inlet valve, being held in position during installation

2. Outlet valve, installed properly in the outlet port during

installation