Service Manual

Single Stage Snowthrower Service Manual 5 - 19

DRIVE SYSTEMS

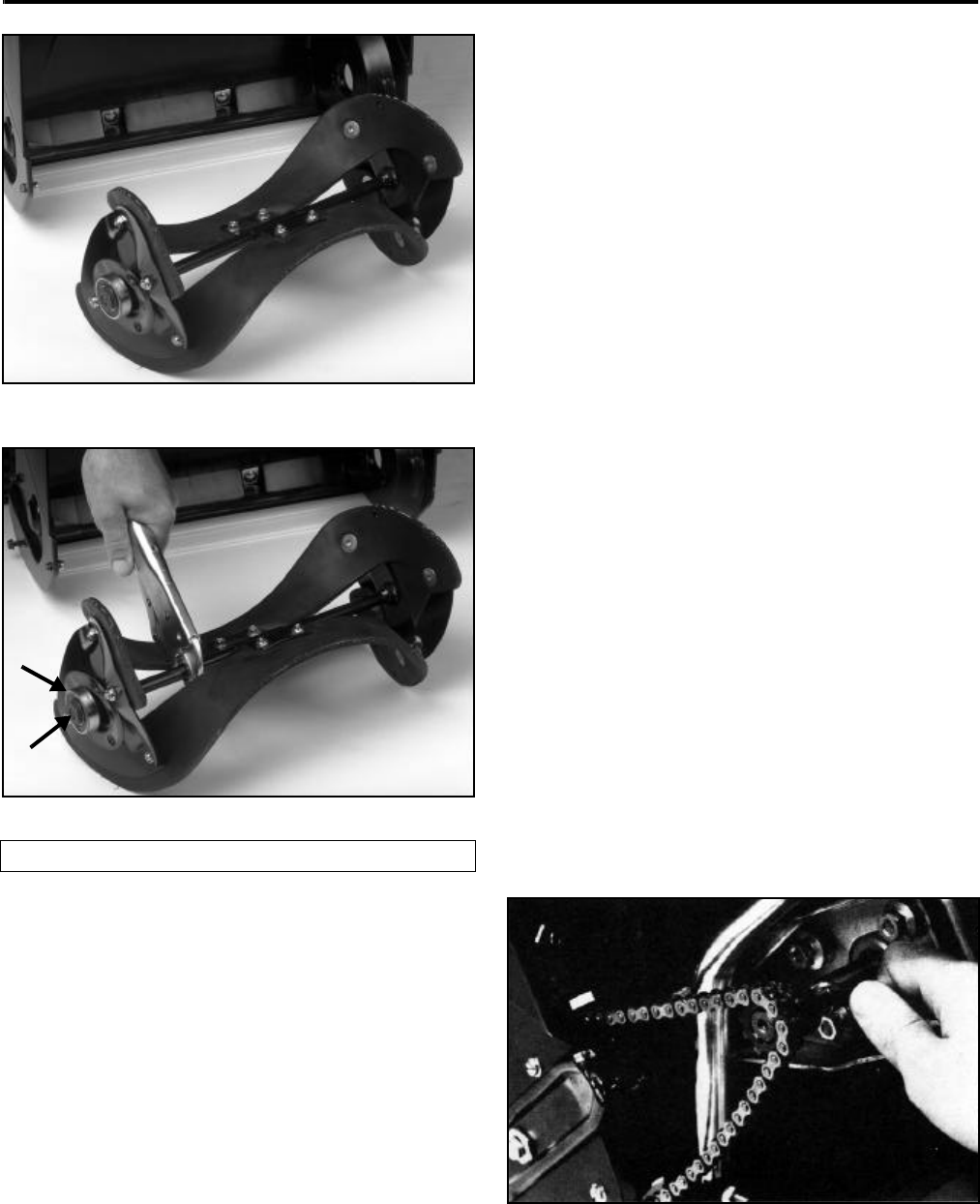

Figure 102 1854-22

Figure 103 1854-21

NOTE: Do not damage the splines or threads in an

attempt to hold the shaft while removing the nut.

New bearings can now be installed on the shaft.

Tighten the nut retaining the right side bearing

(opposite the drive) to 200 - 300 in·lbs.

Assembly

After the new bearings are installed, the rotor can be

reinstalled. Insert the drive side first and push the rotor

towards the drive side, spread the rotor housing, and

insert the non drive side into the hole in the housing.

20” CCR Style

The 20” CCR rotor has only minor differences when

compared to the Powerlite. The rotor pulley is attached

to the rotor shaft with a key and a bolt (later models

have the key built into the pulley). The bearing

retainers are slightly different in that some of them

have threaded studs in place of bolts. On the side

opposite the drive, the outer bearing flange is a

separate part. With the exception of these things, the

Powerlite procedure is used.

DRIVE SYSTEM (CHAIN) SNOW PUP -

S-140

The Toro chain drive system, found on all Toro 14” and

21” single stage snowthrowers has not changed to any

great degree since originally designed for the first

Snow Pup in 1965.

Lubrication:

All the bearings used on the Toro 14” and 21”

snowthrowers are lubricated for life at the factory and

require no additional lubrication. However, a few drops

of light machine oil on the drive chain once a year will

adequately lubricate the chain and sprockets.

Components And Operation

The major components to the 14” and 21” chain drive

system include the engine sprocket, impeller sprocket

and drive chain (Figure 104). Power is transferred

from the engine sprocket, which is keyed to the engine

crankshaft, by a chain to the larger impeller sprocket

fastened to the rotor halves.

Figure 104 0217-064

(A) Bearing (B) Nut

A

B