Service Manual

ProcedureforCuttingDeckMotorCaseDrainLeakageTest

Note:Overaperiodoftime,adeckmotorcanwearinternally.Awornmotormay

by−passoiltoitscasedraincausingthemotortobelessefcient.Eventually,

enoughoillosswillcausethedeckmotortostallunderheavycuttingconditions.

Continuedoperationwithaworn,inefcientmotorcangenerateexcessiveheat,

causedamagetosealsandothercomponentsinthehydraulicsystemandaffect

qualityofcut.

Note:Onemethodtondafailingormalfunctioningdeckmotoristohave

anotherpersonobservethemachinewhilemowingindenseturf.Abadmotor

willrunslower,producefewerclippingsandmaycauseadifferentappearance

ontheturf.

CAUTION

Preventpersonalinjuryand/ordamagetoequipment.Readall

WARNINGS,CAUTIONSandPrecautionsforHydraulicTestingatthe

beginningofthissection.

1.Parkmachineonalevelsurfacewiththecuttingdecksloweredandoff.

Makesurehydraulicoilisatnormaloperatingtemperature,engineisoffand

theparkingbrakeisapplied.

Note:Thesidedeckmotorsareconnectedinseries.Toisolateafaulty

sidedeckmotor,bothmotorsinthecircuitmayhavetobetestedbystarting

withtheleftsidemotorrst.

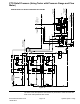

1

3

2

g275067

Figure76

1.Deckmotor(RHshown)3.Casedrainhose

2.Returnhose

2.Disconnecthosefromreturnofthemotortobetested(Figure76).Install

tester(owandpressure)inserieswiththemotoranddisconnectedreturn

hose.Makesuretheowcontrolvalveontesterisfullyopen.

3.Disconnectthemotorcasedrainhose(smalldiameterhose)whereit

connectstohydraulicmanifoldteetting(notatthemotor).Putasteelcap

onthettingattheteetting;leavethecasedrainhoseopen.

Groundsmaster

®

4100-D&4110-D

Page5–63

HydraulicSystem:Testing

13203SLRevF