Service Manual

Table Of Contents

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 : Safety

- 2 : Product Records and Maintenance

- 3 : Engine

- SUBARU SERVICE MANUAL

- 4 : Traction and Reel Drive System

- Table of Contents

- Specifications

- General Information

- Special Tools

- Adjustments

- Service and Repairs

- Reel Drive Belt

- Reel Drive Assembly

- Reel Drive Bearing Housing

- Drum Drive Belt

- Drum Drive Idler Assembly

- Traction Drums

- Differential Assembly

- Differential Assembly Service

- Transmission Drive Belt

- Transmission Idler System

- Transmission Reel Drive System

- Removing Seized Reel Clutch Shaft From Transmission

- Transmission Clutch System (1800/2100)

- Clutch Assembly Service (1800/2100)

- Transmission Clutch System (1820/2120)

- Clutch Assembly Service (1820/2120)

- Clutch Shaft Service (1820/2120)

- Transmission Drum Drive System

- Transmission

- 5 : Electrical System

- 6 : Chassis and Controls

- 7 : Cutting Unit

- 8 : Belt Driven Groomer (Optional)

- Table of Contents

- Specifications

- General Information

- Troubleshooting

- Adjustments

- Service and Repairs

- Groomer Belt Replacement (Forward Rotating Groomer Drive)

- Groomer Cover (Counter Rotating Groomer Drive)

- Grooming Reel (Forward Rotating Groomer Drive)

- Grooming Reel (Counter Rotating Groomer Drive)

- Grooming Reel Service

- Grooming Reel Bearing Replacement

- Idler Assembly (Forward Rotating Groomer Drive)

- Idler Assembly (Counter Rotating Groomer Drive)

- Lift Arm Assembly

- Groomer Brush

- 9: Universal Groomer (Optional)

Greensmaster Flex 1800/1820/2100/2120Traction and Reel Drive System Page 4 − 48

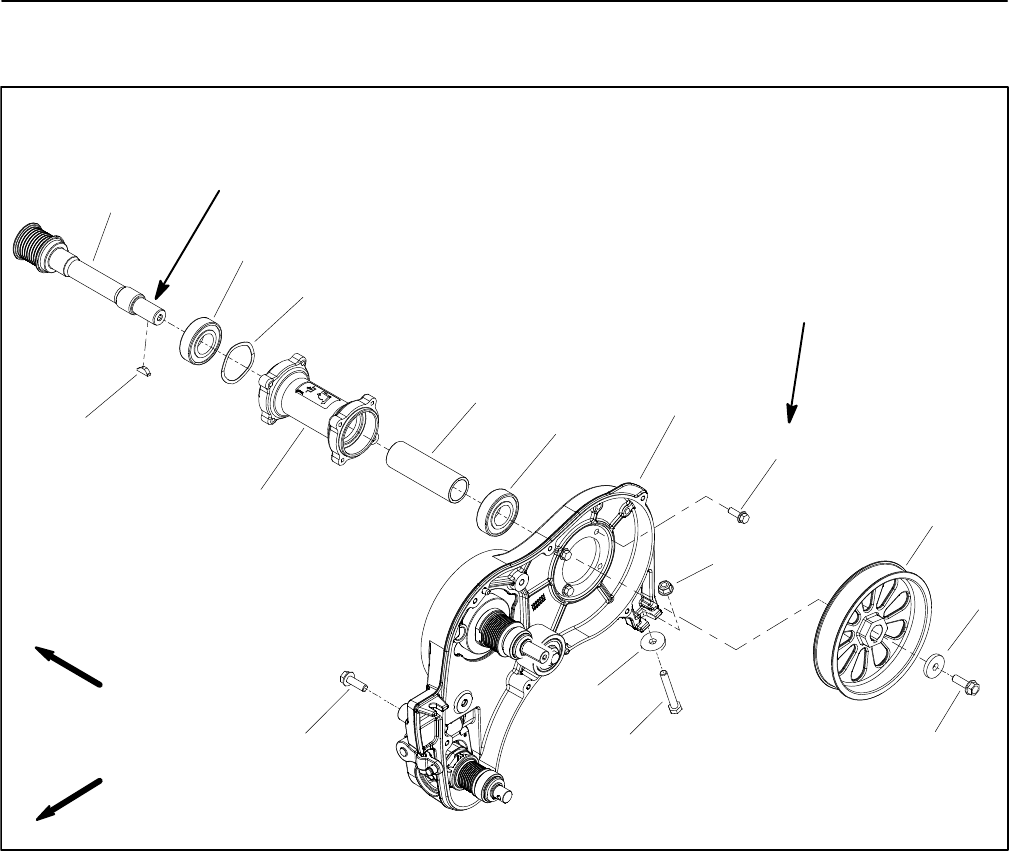

Transmission Drum Drive System

Figure 55

1. Transmission housing

2. Extension housing

3. Ball bearing (2 used)

4. Driven pulley (traction drum drive)

5. Hardened washer (2 used)

6. Driven pulley

7. Spacer

8. Wave washer

9. Woodruff key

10. Washer head screw (4 used)

11. Flange nut

12. Flange head screw (2 used)

13. Cap screw

FRONT

RIGHT

6

5

5

2

4

3

3

1

7

8

9

10

11

1212

13

See text for

tightening

procedure

Lubricant

Antiseize

Transmission removal from the machine is not neces-

sary to service the transmission drum drive system

shown in Figure 55. Transmission drum drive compo-

nents can be accessed by removing the engine from the

frame, removing the transmission cover and then re-

moving the drive belt.

Disassembly (Fig. 55)

1. Park machine on a level surface. Make sure engine

is OFF.

2. Remove transmission drive belt (see Transmission

Drive Belt in this section).

3. Remove flange head screw (item 12) and hardened

washer (item 5) that secure driven pulley (item 6) to

shaft. Slide pulley from shaft. Locate and retrieve wood-

ruff key (item 9).

4. Remove drum drive belt from machine (see Drum

Drive Belt in this section).

5. Slide traction drum drive driven pulley (item 4) from

extension housing.

6. If necessary, remove ball bearings (item 3), spacer

(item 7) and wave washer (item 8) from extension hous-

ing.