Samsung 2 Door 2 Drawer Convertible Side by Side Training Manual RM255BARB RM255BASB RM255BABB Maytag Technical Institute, 2006 L2006-028

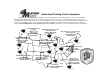

Authorized Training Center Campuses Maytag maintains an affiliation with ten institutions in the US and Canada to offer technical training sessions focused on Maytag branded product. Maytag supplies the course content and product but each school operates as an independent agent and collects fees accordingly. All training sessions include classroom (30%) and lab time (70%) and cover both basic and advanced troubleshooting techniques.

WARNING IMPORTANT SAFETY NOTICE This service guide is for service technicians with adequate backgrounds and electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage.The manufacturer or dealer cannot be responsible for the interpretation of this information. SAMSUNG ELECTRONICS AMERICA, INC. Technical Service Guide Copyright 2005 All rights reserved.

CONTENTS PRECAUTIONS ...................................................................................5 PRODUCT SPECIFICATIONS ...........................................................8 OPERATING INSTRUCTIONS & INSTALLATION........................13 DIASSEMBLY and REASSEMBLY...................................................24 TROUBLESHOOTING........................................................................37 WIRING DIAGRAM...........................................................................

1. PRECAUTIONS(SAFETY WARNINGS) Unplug the refrigerator before making any repairs or any replacements. Avoid electric shock. Use rated components for the replacements. Check that they have the correct model number, rated voltage, rated current, operating temperature and so on. On repair, be sure that the wires such as harness are bundled tightly and are not exposed by water. Bundle wires tightly in order not to be detached by an the external force.

PRECAUTIONS(SAFETY WARNINGS) Read all instructions before repairing the product, and follow to the instructions in order to prevent danger or property damage. CAUTION/WARNING SYMBOLS DISPLAYED Warning Caution SYMBOLS means “Forbidden”. Indicates that a danger of death or serious injury exists. means “do not disassemble”.

PRECAUTIONS(SAFETY WARNINGS) ❈ Please ler users know following warnings & cautions in detail. Warning & Caution Do not allow users to put glass bottles or similar in the freezer. Do not allow users to store narrow and long bottles or foods in a small multi-purpose room. Do not allow users to store pharmaceutical products, scientific materials, etc., in the refrigerator. Freezing the contents may cause . It may hurt you when the refrigerator door is opened and closed resulting in stuff falling down.

2. PRODUCT SPECIFICATIONS 2-1) Introduction of main functions...................................................8 2-2) Model Specifications..................................................................9 2-4) Electric Parts Specifications.......................................................10 2-6) Optional Material Specifications................................................

PRODUCT SPECIFICATIONS 2-1) Introduction of main function THE SAMSUNG side by side refrigerator has the following characteristics: TDM System(Time-Divided-Multi-evaporator system) • Each compartment has one evaporator, so this refrigerator has 4 evaporators. Also, microprocessors and a refrigerant control valve control the refrigeration cycle of the 4 evaporators to achieve high efficiency and high humidity in the fridge.

PRODUCT SPECIFICATIONS 2-2) Model Specification Item Specification RM25 Dispenser without beverage station Net Capacity Total 24.8 ft3 Fridge 11.6 ft3 Freezer CR 7.0 ft3 Fresh Select Zone 3.8 ft3 CF 2.4 ft3 Arctic Select Zone 7 1 38 8 35 4 70 Rated Voltage and Frequency 115V/60Hz Motor Rated Power Consumption 183W Electric Heater Rated Power Consumption 470W Refrigerator Type Indirect Cooling Method Refrigerator Refrigerant R-134a Refrigerant Input Amount 235g(8.

PRODUCT SPECIFICATIONS 2-4) Electric Parts Specification Specification RM25 Item Model Freezer Components Compressor Evaporator Model Starting type Oil Charge Freezer Fridge CR Fresh Select Zone CF MK183C-L2U R.S.C.R FREOL SPLIT FIN TYPE SPLIT FIN TYPE SPLIT FIN TYPE SPLIT FIN TYPE Arctic Select Zone Condenser Dryer Forced and natural convection type Molecular sieve XH-9 F capi 0.85 3300mm(0.033 R capi 0.85 3000mm(0.033 C capi 3.56 650mm(0.

PRODUCT SPECIFICATIONS Specifications Items Model Dispenser Defrost-Heater(FRE) Conducting F Defrosting 200W Defrost-Heater(REF) Conducting R Defrosting 80 W Defrost-Heater(CF) Conducting CF Defrosting 100 W Defrost-Heater(CR) Conducting CR Defrosting 80 W DRAIN PIPE(FRE) Conducting F Defrosting 5W DRAIN PIPE(REF) Conducting R Defrosting 5W DISPENSER Heater Interlock with F-FAN 7W WATER PIPE Heater - 5W WATER TANK Heater - 3W 60 Bimetal Electric Components Home Bar (140 Conden

PRODUCT SPECIFICATIONS 2-6) Optional Material Specifications Photograph Part Name Part Code FILTER WATER-ASSY DA29-00012A ASSY-INSTALL FILTER DA97-01469D INCANDENT LAMP 4713-001194 Refrigerator : 3pcs Freezer : 2pcs 120V, 40W INCANDENT LAMP 4713-001172 CF : 1pcs CR : 1pcs 130V, 30W 12 Remarks

3. OPERATING INSTRUCTIONS & INSTALLATION 3-1) Digital Panel...........................................................................................14 3-2) Temperature Control Operation .............................................................14 3-3) Power Freeze and Vacation Operation...................................................15 3-4) Lock Function .......................................................................................

OPERATING INSTRUCTIONS & INSTALLATION 3-1) Digital Panel Freezer Fridge Arctic Select Zone (CF) Fresh Select Zone (CR) 3-2) Temperature Control Operation 1) Temperature Selection for the Freezer Compartment 1-1) There are automatic temperature asettings of -2 for the freezer compartment and 38 for the fridge compartment when initially applying electric power after installing refrigerator. The numbers on the display represent the inside temperature of the refrigerator product.

OPERATING INSTRUCTIONS & INSTALLATION 3-3) Power Freeze and Power cool Operation 1) Power Freeze Operation 1-1) Select 'Power Freeze' by pressing the freezer compartment button. If 'Power Freeze' function is selected, icon display immediately changes to show the newly selected condition but actual function starts to operate after 10 seconds.

OPERATING INSTRUCTIONS & INSTALLATION 4) At Initial Power On 4-1) At initial power on of fridge product when temperature in the freezer compartment is not lower than 14 and temperature in the fridge compartment is not lower than 50 , if power freezing and power cool functions are selected, operation will be different from the above functions. 4-2) In this case, R-FAN turns off for a little while if power freezing is selected whereas F-FAN turns off for a little while if power cool is selected.

OPERATING INSTRUCTIONS & INSTALLATION => ICE-MAKER stops operation if function of ICE OFF has been selected. After if cubic / crushed are selected, then water is supplied. If cubic / crushed are selected, now you can be promptly provided with ice only that was already formed before selecting ice off. 1-7) When drawing out ice, this is extracted after DISPENSER SWITCH is depressed and ICE COVER is completely opened.

OPERATING INSTRUCTIONS & INSTALLATION 3-8) ICE-MAKER Function (applies only for model with dispenser function) This ICE-MAKER function is option specification so as to be drawn to the function explanation for relevant model. ICE-MAKER is model attached with unit equipment where is furnished function of automatic ice making so that ice may be made in container inside the freezer compartment and may be drawn out by using ice dispenser under storage status ==> The equipment.

OPERATING INSTRUCTIONS & INSTALLATION 2) Water Supply Function 2-1) After finishing the ice extraction operation (initial ice extraction operation, normal ice extraction operation and ice extraction operation of test function) and performing the ice receptacle horizontality operation, if it is judged to have attained horizontality, then there is executed operation of water solenoid located in refrigerator machine compartment for time check function so as to supply water into the ice maker receptacle.

OPERATING INSTRUCTIONS & INSTALLATION 4-2) Step 2 : operation is to overturn tray in order to separate the ice in the ice tray where tray is overturned by direction rotation of ice extraction motor. -In case the storage container is full ice: if the ice extraction S/W is ON again before 3.

OPERATING INSTRUCTIONS & INSTALLATION Reverse rotation : CCW Forward rotation : CW (1) (2) (6) Return Pulse Ice extraction S/W Return Pulse in case of full ice : occurs at forward direction rotation Maximum torsion point Horizontal position Figure - ice extraction and horizontality operation in case of full ice (in reference to the ice extraction S/W) 5) Test Function This function is useful when there is a need for forced operation for testing purposes, A/S, cleaning etc.

OPERATING INSTRUCTIONS & INSTALLATION 6-4) Display lamp is directly extinguished right at the stop selection, but it maintains stop condition after the completion of final water supply if water supply, ice extraction or horizontality noise is under progress. 7) At test operation by test key, ice tray operates regardless of F compartment door opening. This function basically stops the operation if the F compartment door is opened , so that noise may be minimized.

OPERATING INSTRUCTIONS & INSTALLATION 3-10) Arctic Select Zone Function 1) Arctic Select Zone is set to Freeze at initial POWER ON. 2) The function is set and changed as follows by pressing the Arctic Select Zone button. Freeze Soft Freeze Cool Power Freeze 3) If pressing the button for initial setting of Arctic Select Zone for 3 seconds, buzzer sound is heard and simultaneously Arctic and Fresh Select Zones are converted to a function setting mode.

OPERATING INSTRUCTIONS & INSTALLATION FUNCTION OPERATION SPECIFICATION Cool Fresh Select Zone temp. is controlled by interlock with the set temp. (33.8 ~ 44.6 ) of the Fridge compartment Fresh Fresh Select Zone, 37.4 Soft Freeze Fresh Select Zone, 23 Chill Fresh Select Zone, 30.

OPERATING INSTRUCTIONS & INSTALLATION 1) Forced Start Operation Function 1-1) Forced start operation is selected if the test key is pressed once while in the test mode. At that time the buzzer executes an alarm by making a beep sound. 2-1) If forced start operation is selected , then COMP. operates immediately without a 5 minute delay, regardless of operating mode. If it is during defrosting, defrosting shall promptly stop. 3-1) If forced start operation is selected, then the COMP.

OPERATING INSTRUCTIONS & INSTALLATION 3-13) Alarm Function 1) Button Touch Sound (Refer to Sounds Table) 1-1) When touching each button on the control panel, an input confirmation sound is generated (see the following table), according to each operating condition.

OPERATING INSTRUCTIONS & INSTALLATION 3-15) Self-Diagnostics Function 1) Self-Diagnostics Function at Initial POWER ON 1-1) MICOM judges internally by itself within several seconds whether there is any error in temperature sensor if electricity is initially applied to the refrigerator. 1-2) If an inferior sensors are found as the result of Self-Diagnostics operation, all relevant display LEDs are flickering at 0.5 second interval. But no alarm sound is generated separately.

OPERATING INSTRUCTIONS & INSTALLATION Self-Diagnostics Checklist No BAD ITEM TROUBLE STATUS 1 I/M-SENSOR Ice maker sensor system abnormality 2 R-SENSOR R Compartment sensor system abnormality 3 R-DEF-SENSOR System abnormality of defrosting sensor for of R compartment 4 R-FAN ERROR I/M Fan motor system abnormality in R compartment 5 FUNCTION ERROR Ice maker operation abnormality 6 - 7 R-DEFROSTING ERROR Abnormality in defrosting system for R compartment 8 CR-SENSOR CR compartment se

OPERATING INSTRUCTIONS & INSTALLATION Error items of self-diagnostics No ITEM TROUBLE 1 I/M-SENSOR Electric wire cut, short-circuit, contact failure, sensor housing missing, while in case of displaying a temperature defect, it is only displayed when the sensor detected temperature is not lower than 122 nor higher than -58 2 R-SENSOR Electric wire cut, short-circuit, contact failure, sensor housing missing, while in case of displaying a temperature defect, it is only displayed when the sensor detecte

OPERATING INSTRUCTIONS & INSTALLATION No ITEM TROUBLE 16 F-DEF-SENSOR Electric wire cut, short-circuit, contact failure, sensor housing missing, while in case of displaying a temperature defect, it is only displayed when sensor detection temperature is not lower than 122 nor higher than -58 17 F-FAN ERROR Error is displayed in case there is a contact failure on the feedback signal line, motor wire missing or defect of the motor itself, when operating the relevant fan motor.

OPERATING INSTRUCTIONS & INSTALLATION 3-16) Load Condition Display Function 1) If the freezing setting + the refrigeration setting keys are pressed simultaneously for about 6 seconds under normal operation condition, the freezer compartment and the refrigerator compartment temperature setting displays go on ALL ON/OFF for about 2 seconds with a 0.5 second interval.

OPERATING INSTRUCTIONS & INSTALLATION 3-17) Operation Condition Recovery Function in Case of Power Outage 1) In case of momentary electricity interruption, customer's NON-SENSE CALL would arise if PANEL DISPLAY is initialized. To prevent this, initialization or recovery(of previous operation status) is operated by way of judging the temperature in the freezer compartment.

OPERATING INSTRUCTIONS & INSTALLATION Key Functions After Converting to Option Mode ITEM DOWN KEY OPTION VALUE DOWN KEY VALUE ITEM ITEM UP KEY OPTION VALUE UP KEY KEY FUNCTION Refrigerator Compartment key ITEM DOWN Fresh zone, Freezer keys ITEM UP Freezer Compartment key OPTION VALUE DOWN Arctic Select Zone key OPTION VALUE UP 1) For example if you wish to shift the freezer compartment standard temperature down by 37.4°F by adjusting option, you may proceed as follows.

OPERATING INSTRUCTIONS & INSTALLATION 4) If "6" is set as shown in the following option table for the freezer compartment after setting at "0" for the refrigerator compartment, standard temperature of freezer compartment is lowered by -26.6°F. (Refer to the figure of temperature change for freezer compartment) : If you wait 20 seconds after completing the adjustment, the MICOM saves the set value on EEPROM and returns to normal display and the option setting mode is canceled.

OPERATING INSTRUCTIONS & INSTALLATION Set Value F Compartment Set value for temperature display 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Option Value 32 31.1 30.2 29.3 28.4 27.5 26.6 25.7 32.9 33.8 34.7 35.6 36.5 37.4 38.3 39.2 Application Example) When to lower the reference temperature of the Freezer Compartment to 26.

OPERATING INSTRUCTIONS & INSTALLATION The following options apply only to models attached with ice maker. In case of basic model, the following items cannot be set. 3) Water Supply Quantity Control Function, for the Ice Maker Automatic water supply quantity control option by flow sensor. 5) Temperature Change of Ice Making Sensor for Ice Maker This is the judgment reference temperature for the ice making sensor to check whether the ice in ICE MAKER has been completely frozen.

5. DISASSEMBLY AND REASSEMBLY 5-1) Door Assy 5-2) Door Sub Parts Control Panel………………………………………………………....…… 47 Door Gasket……………………………………………………………….. 47 Door Handle……………………………………………………………….. 47 5-3) Refrigerator Compartments Refrigerator Door Light Switch…………………………………………... 48 Tempered Glass Shelf……………………………………………………… 48 Refrigerator Light………………………………………………………...... 48 Plastic Drawers in the Refrigerator……………………………………........ 48 Gallon Door Bin ………………………………………………………........

DISASSEMBLY AND REASSEMBLY 5-1) Door Assy Removing the Front Leg Cover FRONT LEG COVER RIB HOOK Pull the leg-font-cover down with both hands and remove it by lifting it up with the upper rib. And then, disengage the lower hooks. Removing the Freezer Door NOTE • Lift the door straight up. • Be careful not to pinch the water tubing and wire harness on the door. • Place doors on a protected surface.

DISASSEMBLY AND REASSEMBLY Removing the Freezer Door 2) Remove the water tube by pressing the coupler-ring (➂) and pulling the water tube (➃) away. NOTE Do not cut the water tube. Separate it from the coupler. 3) Pull and open the latch (➄), and take off the door hinge (➅) along the arrow. Be careful when removing the door to ensure that it does not fall on you. 4) Remove the door from the lower hinge (➆) by carefully lifting the door (➇). 5) Remove hinge screws (➈).

DISASSEMBLY AND REASSEMBLY Removing the Refrigerator Door 1) With the door closed, remove the upper hinge cover (➀) using a screwdriver. 2) Pull and open the latch (➁), and take off the door hinge (➂) along the arrow. 3) Remove the door from the lower hinge (➃) by lifting the door (➄). 4) Remove the hinge screw (➅).

DISASSEMBLY AND REASSEMBLY How to Disassemble the Fresh Select Zone Door 1) Open the Fresh Select Zone Door. 2) Take out the box in the Fresh Select Zone. 3) Remove two screws holding it to the liner on the left side of the rail. If you pull out the door completely, you will find a screw between bracket rail and liner. Also the other screw is located in the center of rail on the liner. 4) Remove two screws holding it to the liner on the right side of the rail.

DISASSEMBLY AND REASSEMBLY Reattaching the Freezer Door 1) Reattach the hinge screws (➀). 2) Place the hole in the bottom of the door (➂) over the hinge (➁). 3) Insert the upper hinge shaft (➃) into the hole (➄). After levelling between the hinge brackets (➅). Reattach and close the latch (➆). 4) Connect the wires (➇) and the water tube (➈). 5) Put the front part of the upper hinge cover (➉) on the front part of the upper hinge ( 11) and reattach it from the front part of the upper hinge cover first.

DISASSEMBLY AND REASSEMBLY Reattaching the Refrigerator Door 1) Reattach hinge screws (➀). 2) Place the hole in the bottom of the door (➂) over the hinge (➁). 3) Insert the upper hinge shaft (➃) into the hole (➄). After levelling between the hinge brackets (➅). Reattach and close the latch (➆) along the arrow. 4) Put the front part of the upper hinge cover (➇) on the front part of the upper hinge (➈) and reattach it from the front part of the upper hinge cover first. 5) Reattach the hinge screw (➉).

DISASSEMBLY AND REASSEMBLY Reattaching the Front Leg Cover FRONT LEG COVER RIB HOOK Hold the leg-front-cover with both hands and insert it while sliding the hooks along the guide at the bottom. Then, lift up the leg-front-cover a little bit and snap the upper ribs into the locking tabs. LEVELLING If the front of the appliance is slightly higher than the rear, the door can be opened and closed easier. The appliance tilts down to the right.

DISASSEMBLY AND REASSEMBLY How to Disassemble the Arctic Select Zone Door 1) Open the Arctic Select Zone Door. 2) Take the box out of the Arctic Select Zone. 3) Remove two screws holding it to the liner on the left side of the rail. If you pull out the door completely, you will find a screw between bracket rail and liner. Also the other screw is located in the center of rail on the liner. 4) Remove two screws holding it to the liner on the right side of the rail.

DISASSEMBLY AND REASSEMBLY Connect the water line to the refrigerator. 1) Slip the compression nut and plastic ferrule through the plastic tube. 2) After inserting the sleeve, tighten the compression nut onto 1/4” compressionfitting(union). Compression Nut Ferrule Sleeve Do not overtighten the compression NOTE nut. Compression fitting 3) Slip the compression ferrule and nut on copper (or plastic) tubing as shown. Tighten the compression nut onto the compression fitting(union).

DISASSEMBLY AND REASSEMBLY 5-2) Door Sub Parts Control Panel Door Gasket 1. Insert a flat-blade screwdriver in the slot as shown, and unlock the tabs. 2. Lift it up as shown 3. Disconnect the wire connector. Door Handle The door handles allow access into the refrigerator and freezer. They are front mounted with screws. 1. Remove the screw on the upper part of the handle 2. Lift the handle upward screw 47 The door gasket is a molded gasket set into a channel located in the door liner. 1. Open the door.

DISASSEMBLY AND REASSEMBLY 5-3) Refrigerator Compartments Refrigerator Door Light Switch Tempered Glass Shelf The refrigerator has a door light switch located in the upper right corner for the refrigerator. 1. Use a small flat-blade screwdriver to unlock the locking tab and pull the switch out until you can see the wire connector. These shelves allow the storage of larger items and easy access by pulling out. 1. Pull the shelf out as far as it goes. 2. Lift it up and remove it.

DISASSEMBLY AND REASSEMBLY 5-4) Freezer Compartments Door Bin in Freezer Plastic Drawer in Freezer The door bins allow storage of perishable items. 1. Push the bin up and slide it out. Drawers are designed for storage of meat and dried foods. The drawers are located in the lower portion of freezer. 1. Pull out the drawer as far as it goes. 2. Tilt the drawer up and pull it out until it is removed.

DISASSEMBLY AND REASSEMBLY Ice Dispenser Ice Maker The ice dispenser is located in the upper portion of freezer. This assembly is to store and dispense ice made by the icemaker. 1. Lift the ice bucket up and slide out the ice dispenser assembly . In order to assemble the Icemaker Kit. 1. Align the Geard Motor Shaft with Ice Tray hole to assemble. 2. Slide the IceMaker Kit like the arrow(1) 3. Connect the ice maker wire connector. 4.

DISASSEMBLY AND REASSEMBLY Auger Motor Case Upper Ductwork This shelf is designed to support the ice maker & ice dispenser. 1. Remove the screws(2) on the side of the case 2. Slide the case out while disconnecting the wire connector. 1. Remove the screw cap and screw. 2. Slide the upper fan ductwork out while disconnecting the wire connector (Lamp and Thermistor).

DISASSEMBLY AND REASSEMBLY PARTITION IN THE FREEZER EVAPORATOR COVER The Partition is located in the lower part of the freezer.Before separating the partition,take out all the shelves and cases which are above the partition. For the disassembly of evaporator cover, water tank and partition should be disassembled first.. 1. Remove the cap screws(2 pieces), and then remove other screws(4 pieces). 1. Unscrew the partition(a screws). screws 2.

DISASSEMBLY AND REASSEMBLY EVAPORATOR FAN MOTOR IN ARCTIC SELECT ZONE The Evaporator fan motor in the arctic select zone is located in the lower part of evaporator cover. 1. Remove the screws(2 pieces)attached to the Fan-Cover. Evaporator Fan Motor The evaporator fan is located in the lower rear of the refrigerator. This fan circulates cold air in the refrigerator. 1. Remove the screws(4 pieces) from the four corners of fan bracket. 2. Take the fan motor assembly off. Evaporator in Freezer 2.

DISASSEMBLY AND REASSEMBLY Freezer Thermistor Water Tank The refrigerator thermistor is located inside of the light cover of the refrigerator The water Tank is located in the lower part of the refrigerator. Before disassembling the Water Tank, take out all shelves and cases located in front of the Water Tank. 1. Unscrew the water tank(2 screws)to separate, and lift it up. 1. Unscrew the upper left part of Ductwork, and pull the projected part of the Thermistor cover to separate. 2.

DISASSEMBLY AND REASSEMBLY 2. Pull the upper part of the evaporator cover slightly. 3. Insert the flat-tip screwdriver into the center of insulation-partition, and lift it up slightly to open the door in the lower compartment. then lift the insulation-partition upward to separate. 3. Separate the housing terminal connected to the right side of evaporator cover, and lift it up carefully using both hands.

DISASSEMBLY AND REASSEMBLY Evaporator in Fridge Refrigerator Thermistor The evaporator is located in the bottom of the refrigerator. 1. Take off the partition in the refrigerator. 2. Take off the evaporator cover in the refrigerator. 3. Disconnect the wire connector.(Heater and Thermistor) 4. Desolder the capillary tube and the suction line from the evaporator. 5. Remove the evaporator. 6. With a file, score the capillary tube just upstream of the soldered point.

DISASSEMBLY AND REASSEMBLY 2. Unscrew the lower part and the center of the duct-work. Evaporator Fan Motor in Fresh Select Zone TM The Evaporator Fan Motor in the Fresh Select Zone is located in the lower part of the cooling compartment. 1.Unscrew the fan-cover. (2 screws) screws 2. Separate the insulation covering the fan by removing the sponge and tape. 3. Unscrew (2 screws) the upper part of the evaporator cover to take out the duct work by pulling. 3.

DISASSEMBLY AND REASSEMBLY Machine Compartment Sub-condenser Electric Box 1. Disconnect the power cord of the refrigerator. 2. Remove the fixing screws (8) of compressor cover. The sub-condenser is located in the machine compartment. Heat is released by the condenser fan. 1. Desolder the compressor discharge the sub-condenser outlet. 2. Take out the sub-condenser. Desoldering Point 3. Slide up and take off the compressor cover to see the machine compartment.

DISASSEMBLY AND REASSEMBLY REMOVING THE ARCTIC SELECT ZONE ACCESSORIES Open the Arctic Select Zone Door. Hold the front side of cover, and pull it out. Open the door, and pull the Arctic Select Zone Door out to the end to take the basket out. NOTE • Empty the basket before taking it out. Lift the front side of basket first, and then take it out carefully. REMOVING THE FRESH SELECT ZONE ACCESSORIES Open the Fresh Select Zone door. Hold the front side of upper drawer, and pull it out.

DIAGNOSTIC 6-1) If power is not ON Caution! At the power of main PCB, the 115V AC and a high-voltage over DC 170V occur. Please be careful wih repair and measurement To check the main PCB, please see the “operation descriptions and references” in the manual. Start Is it plugged in? NO YES Check at the SMPS PBA. Is 115V AC applied to both terminals of CN1? NO Plug in again and check for loose plug. YES Check the connection and assembly of electric wires.

DIAGNOSTIC 6-2) If the compressor doesn’t work normally Start NO Does 5 min pass after COMP. OFF? Recheck the comp after a 5 min. YES See the TEST FUNCTION in the manual. Did buzzer sound on forced operation? YES (Check certainly after forced start.) NO Exchange MICOM and PCB. NO Replace IC73 Driver IC(TD62083AP). YES Does compressor work with forced operation? NO Is refrigerator sensor normal? Voltage value of MICOM pin No.

DIAGNOSTIC 6-3) If the defrost function doesn’t work Start Is defrosting sensor by self-diagnosis normal? NO Exchange and troubleshoot the corresponding sensor. YES Are all defrosting heaters normal? NO YES Is temperature of the corresponding defrosting sensor below 23 ? NO Check temp. fuse, breaking of heater contact of wire, and so on. Run forced operation for a specified period. YES Perform forced defrosting for F and R room one at a time.

DIAGNOSTIC 6-4) If there is a trouble with self-diagnosis(sensor failure) - Error in sensor can be seen on the front display of refrigerator. If sensor failure is found when power is initially impressed to refrigerator, the product will not work, and display is repeatedly blinking in the trouble occurred sensor. - Even if sensor has failure during the oeration refrigerator will not stop working but can’t run the normal cooling operation because of being operated in the Emergency Operation mode.

DIAGNOSTIC 6-5) Alarm Sounds continuously(related to the buzzer) 1) If “Ding-Dong” sounds continuously Start Yes Is the door slightly open? No Is moisture penetrated into the door S/W? Freezer door MICOM No. 49, Fridge door MICOM No. 47 CF - door micom no.50 CR - door micom no.48 – Regular voltages are 5V to Open : 0V to Close. Yes Remove causes after understanding the conditions for interference by door gasket, food etc.

DIAGNOSTIC 3) If the buzzer doesn’t sound This model is equipped with the buzzer on the Panel PCB. If buzzer doesn't sound in case of button operation, forced operation or door opening, separate the panel PCB first to check if buzzer is broken or there are any soldering failures. It is not easy to troubleshoot it as the Panel PCB is made with SMD parts.

DIAGNOSTIC 6-6) If the panel PCB is not working normally: 1) Where all lights of the panel PCB are disabled, or only some lamps are disabled. Start See the electric circuit diagram or connection diagram attached to the backside of refrigerator. Is the connector on upper hinge cover of freezer inserted normally? YES NO Is the main PCB connector(CN50) inserted normally? NO Reinsert the connector. Troubleshoot contact failure. Reinsert the connector into the main PCB.

DIAGNOSTIC 6-7) If fan motor doesn’t working normaly. This refrigerator uses a BLDC FAN motor and this motor is driven by 8 ~12V DC. Under the normal condition of COMP ON, it is operated together with F-FAN motor. F-Fan motor may not work depending on the conditions. If the door is opened and closed once at a high ambient temperature, the BLDC motor would be operated after 1 minute or delayed longer. Therefore, you are advised not to take it for an error.

DIAGNOSTIC Start NO Is the COMP OFF State? FOR C/R-FAN FOR C/F-FAN Is the voltage DC 0-1V between GND of the main-PCB section and\ CN76 pin No. 5? Is the voltage DC 0-1V between GND of the main-PCB section and CN76 pin No. 2? YES NO NO Is the voltage DC5V between the main PCB section CN No.9 and No.14? Fan works normally. Is the voltage DC5V between the main PCB section CN No.2 and No.7? YES NO Troubleshoot the connections of door S/W. YES Apply power around 5 minutes after the power OFF.

DIAGNOSTIC 6-9) If Ice Cubed or/and Ice Crushed don't work normally Start It operates with the Freezer door closed. Does ice come out when drawing ice? NO YES NO Is there ice in the ice storage bin? Is the ice selection on panel for ice off? YES Check point of contact of ice drawing S/W Check point of contact of door S/W. Check point of contact of ice transfer motor.

DIAGNOSTIC 6-8) If Indoor Lamp of Freezer/Refrigerator doesn’t light Caution! 1. When replacing the indoor lamp of freezer or refrigerator, please turn the power OFF to avoid an electric shock. 2. Please be sure to avoid a burn by the excessive heating of incandescent light bulb. An example of F-Room Lamp is presented as follows. And you may apply the same principle and method to the other indoor lamps.

DIAGNOSTIC 6-10) If Water Drawer doesn't work normally Preliminary Check 1. Stop water supply before disassembling or assembling because water is directly supplied to the water valve. 2. Keep in mind to avoid shock hazard during disassembly because power is always present on one side of wire. Start Check water coming out when pressing water lever at dispenser.

DIAGNOSTIC 6-11) If Dispenser LED Lamp doesn't light Caution 1. Dispenser LED Lamp is working with 12V DC.(=Dispenser LED Lamp has 12V DC power supply.) Anyone without approval or other than the qualified engineer is prohibited to perform the repair or disassembling work due to the danger of high voltage DC current. 2. To replace LED Lamp, the dispenser cover should be disassembled.

9.

PCB DIAGRAM 10-2) CONNECTOR ARRANGEMENT (Main Board) 74

CIRCUIT(SCHEMATIC) DIAGRAM 75

Circuit Descriptions 10-3) CONN ECTOR ARRANGEMENT (SMP S Board) 76

Circuit Descriptions 12-1) POWER BUS This POWER BUS, and SMPS (Switch Mode Power Supply), is an improved efficiency power- convertion circuit for converting AC input voltage to high voltage DC. However, a consistent attention should be paid to the POWER BUS because 115V AC and 170V DC may be generated. The voltage input has AC applied into BD1(Rectifier Circuit) through FUSE(F1) and LF1, and smoothes the rectified voltage through C101(180uF/450V). As a result, DC voltage is applied into the SMPS TRANS.

CIRCUIT DESCRIPTIONS Temp.( ) Temp.( ) Resistance( ) Voltage(V) 98.9 -43.6 -42 4.54 93.7 -41.8 -41 4.52 88.9 -40.0 -40 4.49 84.2 -38.2 -39 4.47 79.8 -36.4 -38 4.44 75.7 -34.6 -37 4.42 71.8 -32.8 -36 4.39 68.2 -31.0 -35 4.36 64.7 -29.2 -34 4.33 61.5 -27.4 -33 4.30 58.4 -25.6 -32 4.27 55.6 -23.8 -31 4.24 52.8 -22.0 -30 4.20 50.2 -20.2 -29 4.17 47.8 -18.4 -28 4.13 45.5 16.6 -27 4.10 43.3 -14.8 -26 4.06 41.2 -13.0 -25 4.02 39.2 -11.2 -24 3.99 37.4 -9.4 -23 3.95 35.7 -7.6 -22 3.91 34.0 -5.8 -21 3.86 32.4 -4.

CIRCUIT DESCRIPTIONS 1) As shown in the Figure, C/F, C/R FAN are connected to the CN75 connector, and FAN MOTOR consists of ND, VCC, FG. 2) If you intend to operate the C/F-FAN or C/R-FAN according to a certain condition in the MAIN PCB, which controls the refrigerator, follow the instructions below. 3) For example, to operate C/F-FAN, a 5V voltage comes out of MICOM #6 first. Then, the 5V voltage is input to IC75 #1 PIN, and the #18 PIN has a changed electric potential from OV to GND.

CIRCUIT DESCRIPTIONS 12-9.

M 25 5 81 LABEL LOCATION MAIN OPTION (the earlier specification which is initially set) 1-VALUE maintain the earlier 3-GOOD initial set specification, prohibit the mixed 5-BETTER use of specifications 7-BEST capacity:CU.FT Products: M-MULTI DOOR R DOOR specifications T : TRIM KIT No marking : BASIC MODEL / Buyer only U.S.

REFERENCE INFORMATION 13-2) Q & A Problem The refrigerator does not work sufficiently or at all The food in the refrigerator is frozen Unusual noises or sounds are heard The front corners and sides of the cabinet are hot; condensation occurs Ice is not dispensed You can hear water bubbling in the refrigerator There is a bad smell in the refrigerator Frost forms on the wall of the freezer wall No water is supplied Possible Causes • Disconnected power plug What To Do • Check that the power plug is pro

REFERENCE INFORMATION Problem Small or hollow cubes Slow ice cube freezing Possible Causes Water filter clogged. Door left open. Temperature control not set cold enough. Orange glow in the freezer Defrost heater is on. Cube dispenser does not work(on some models) Icemaker turned off or water supply turned off. Ice cubes are frozen to the icemaker feeler arm. Irregular ice clumps in the storage container. Water dispenser has not been used for a long time.

REFERENCE INFORMATION 13-3) Additional Information Compressor Sub-condenser Hot Pipe Dryer Step valve R Capillary Tube F Capillary Tube R/CR evaporator C - Capillary Tube CF/F evaporator Suction Pipe comp 3-W ay 84

REFERENCE INFORMATION Refrigerator Freezer 85

Notes:

Be Aware, Be Alert Always work safely.