DisplayMaker Legacy 72UVX and 98UVX - User Manual

Table Of Contents

- Title Page

- 1 Getting Started

- 2 Using the Control Panel

- 3 Ink and Media

- 4 Calibrating the Printer

- 5 Maintaining the Printer

- A Technical Specifications

- B Troubleshooting

- Index

3-36 Edge-to-Edge Printing

Media Properties ◆ Follow the guidelines in this chapter for printing on rigid

media.

◆ The media should have parallel opposite edges with 90-

degree corners. Media that is not exactly square with itself

can be used, but will require extra attention when loading

(see “Loading and Squaring the Media,” below).

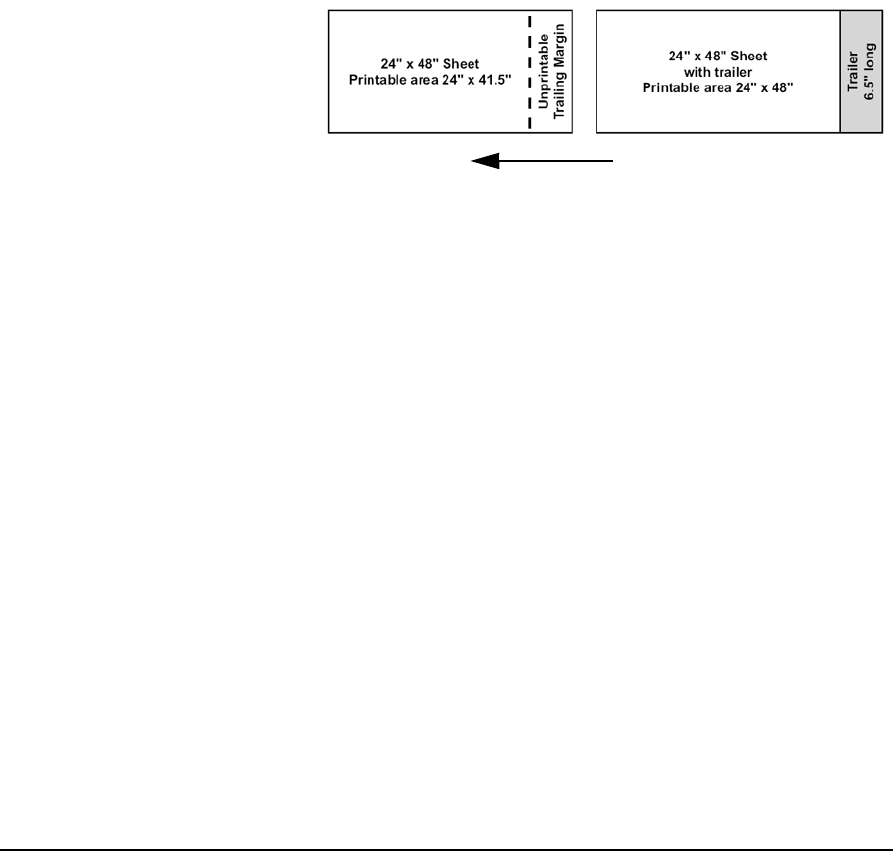

◆ To print to the trailing edge, attach a 6.5 inch (16.5 cm) or

longer trailer of the same media to the trailing edge, so the

pinch rollers can feed the media all the way past the print

zone.

Printer Setup ◆ Tape the platen under the left and right edges of the media

to catch any oversprayed ink. Use a colored tape to allow the

printer to find the media edges. A piece of media printed

with a solid color also works for this purpose. Do not use

white tape or media; the printer uses the contrast between

the media and the platen to find the media edges.

◆ Use the supplied head height gauge to set the printhead

height over the media.

◆ From Menu > Printer Settings > Margin Settings, set the

Right and Left Margin, and Leading Margin to 0 as desired.

Set the Trailing Margin to 6.5 inches (which is the mini-

mum).

◆ Optionally, you can set an Overprint distance between 0 and

0.5 inches to print past the left and right edges (0.125 inches

to 0.25 inches is usually sufficient if the media is reasonably

square and unskewed).

◆ From Menu > Printer Settings > Print Position, center the

image on the media.

◆ When loading the media, report the length as the total

length of the media plus trailer.

Direction of media feed

Fig. 3-18. Attaching a trailer