Datasheet

Table Of Contents

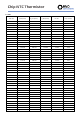

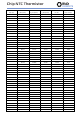

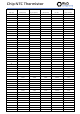

Chip NTC Thermistor

RND is a trademark of Distrelec

Item

Test Methods and Remarks

Standard

Requirements

Solderability

IEC 60068-2-58

• Solder temperature: 245 ± 5℃

• Duration: 10 ± 1s

• Solder: Sn/3.0Ag/0.5Cu

• Flux: 25% resin and 75% ethanol in weight

1. No visible damage

2. Wetting shall exceed 95%

coverage

Resistance to

Soldering Heat

IEC 60068-2-58

• Solder temperature: 245 ± 5℃

• Duration: 10±1s

• Solder: Sn/3.0Ag/0.5Cu

• Flux: 25% resin and 75% ethanol in weight

• The chip shall be stabilized at normal condition for

1~2 hours before measuring

1. No visible damage

2. ∣

∆R25/R25∣

≤5%

3.

∣

∆B/B∣

≤2%

Temperature

Cycling

IEC 60068-2-14

Step

2

3

125 ± 2 ℃

25 ± 2 ℃

1

-40 ± 5℃

30 ± 3min

5 ± 3min

30 ± 3min

5 cycles of following sequence without loading

4

Temperature

Time

25±2℃

5 ± 3min

1. No visible damage

2. ∣∆R25/R25∣≤3%

3.

∣

∆B/B∣

≤2%

Resistance to

Dry Heat

IEC 60068-2-2

1. 125 ± 5℃ in air, for 1000 ± 24 hours without loading

2. The chip shall be stabilized at normal condition for

1~2 hours before measuring

Resistance to

Cold

IEC 60068-2-1

1. -40 ± 3℃ in air, for 1000 ± 24 hours without loading

2. The chip shall be stabilized at normal condition for

1~2 hours before measuring

1. No visible damage

2. ∣

∆R25/R25∣

≤5%

3.

∣

∆B/B∣

≤2%

Resistance to

Damp Heat

IEC 60068-2-78

1. No visible damage

2. ∣∆R25/R25∣≤3%

3.

∣

∆B/B∣

≤2%

1. 40 ± 2℃, 90~95%RH in air, for 1000 ±2 4 hours

without loading

2. The chip shall be stabilized at normal condition for

1~2 hours before measuring

Resistance to

high

temperature

load

IEC 60539-1

5.25.4

1. No visible damage

2. ∣

∆R25/R25∣

≤5%

3.

∣

∆B/B∣

≤2%

1. 85 ± 2℃in air with permissive operating current

for 1000 ± 48

hours

2. The chip shall be stabilized at normal condition for

1~2 hours before measuring

Storage

Storage Conditions

• Storage Temperature: -10℃~40℃

• Relative Humidity: ≦ 75%RH

• Keep away from corrosive atmosphere and sunlight

• Period of Storage: 6 Months after delivery

1. No visible damage

2. ∣

∆R25/R25∣

≤5%

3.

∣

∆B/B∣

≤2%